Innovation is the beating heart of every company that aims to thrive and grow in a continuously developing sector such as EMS, and we at HIGH TECHNOLOGY SYSTEMS are no exception.

Today we are pleased to announce an important step towards our mission of continuous improvement, the implementation of the world’s most advanced 3D AOI system, the OMRON VT-S1080!

But what is 3D AOI and how is it performed?

Automatic Optical Inspection 3D is a state-of-the-art technology that allows us to inspect our products with unprecedented precision and detail.

This technology goes beyond traditional inspection, allowing us to analyse not only the surface, but also the three-dimensional geometry of components.

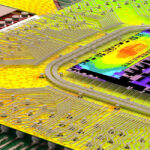

The process begins with four projectors illuminating the product to be inspected and, at the same time, capturing images of the electronic board being analysed, allowing the machine to obtain detailed 3D data on its shape and topography.

The acquired images are then processed by advanced software that, by comparing them with an ideal three-dimensional model of the electronic board under examination, identifies the differences between the real object and the model, and classifies any discrepancies according to their severity.

In this way, the operator can determine which errors require immediate corrective action or not.

In addition, inspection results are recorded and documented so that trends can be tracked and analysed over time, allowing us to improve the production process and prevent future errors.

The Benefits of the 3D AOI, OMRON VT-S1080:

- Unrivalled Accuracy: Thanks to its ability to work in 3D, the VT-S1080 identifies even the finest imperfections, helping to ensure the highest quality products while minimising errors.

- Faster Production: This machine is incredibly fast, allowing us to increase production without compromising quality. This allows us to meet growing market demand more efficiently and effectively.

- Reducing Production Errors: AOI 3D detects potential defects before products leave the production line, minimising waste and associated costs.

- Environmental Commitment: By reducing waste, we actively contribute to more sustainable and environmentally friendly production.

- Staff Development: This innovation has also given us the opportunity to train and further develop the skills of our team, our most valuable asset.

In HTS, innovation is a constant

Innovation is the engine that drives our constant evolution and our commitment to continuous improvement.

This implementation is a tangible sign of our approach to business growth and the importance we attach to quality and efficiency.

We are proud to invest in cutting-edge technologies such as Automatic Optical Inspection 3D to ensure the highest quality and precision in our products, and we will continue to look for new opportunities to innovate and maintain our high standards of excellence so that we can consistently exceed our customers’ expectations.

Take a look at our ‘Technologies and Services’ page, discover the breadth of services on offer and choose what is right for you!

If you want to learn more about our journey towards innovation or have further information about 3D AOI, do not hesitate to contact us at info@htsitaly.it or visit our LinkedIn page.